Pumping massecuite or magma in the sugar industry may be quite different from any other pumping task in several industries due to the nature of the sweet products. The massecuite tends to be heavy and very dense, once the total solid content is considerably high. Therefore, slow speed and positive displacement pumps are commonly used. Massecuite leakage through shaft sealing gaskets is a common problem in the market. Thus, an adequate sealing is of most importance. Once massecuite is highly abrasive, suitable fabric materials must be properly employed.

The massecuite pumps supplied by Alpina Orion have two elliptical lobes, manufactured with nodular cast iron. Pump housing is casted in carbon steel, the scrapers are manufactured in bronze and the shaft uses high quality carbon steel. In order to minimize the massecuite leak around the shaft, two heavy-duty external rolling bearings are employed. Thus, the wearing of sliding bearings is avoided and so, the misalignment of the pump shaft. The selected external bearings are easy to be assemble or disassembled in the shaft. The pump driving gear can be easily arranged in both right and left mountings. All one needs to do is to change the shaft mounting position.

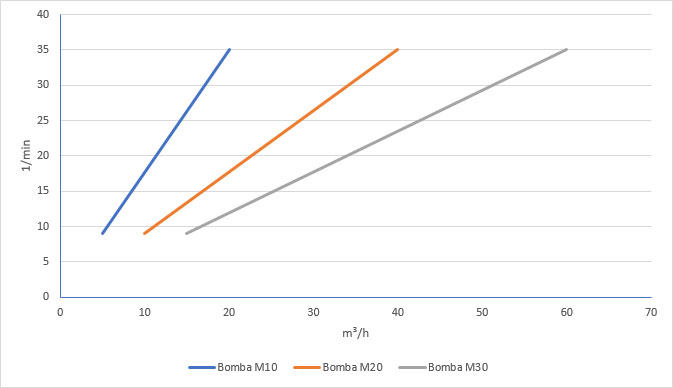

The Alpina Orion massecuite pumps cover a wide range of pumping capacity, from as low as 5m³/h up to 60m³/h. For the lower capacities pumps the inlet and outlet connecting flanges are round, with ND150mm or ND225mm. For higher pumping capacities, rectangular flanges are employed.

The mobile parts of the pumps are of very easy maintenance and low cost.

The lobe pump from Alpina Orion is perfectly suitable in sugar applications such as massecuite, magma or crystal-seed pumping.